Imagine a world with more durable, eco-friendly packaging, coatings, and flexible electronics. Researchers at Universiti Teknologi Malaysia (UTM) are making this vision a reality by developing a novel method to enhance the properties of polyvinyl alcohol (PVA) films using graphene. PVA is a water-soluble polymer, often used in packaging, but improvements in its strength and durability are needed.

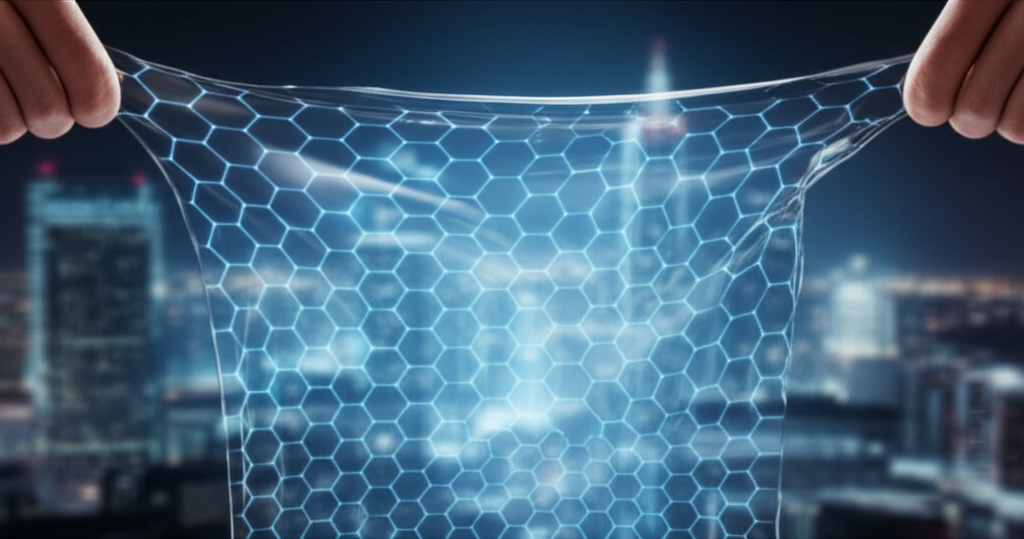

Graphene, a single-layer of carbon atoms arranged in a honeycomb lattice, has exceptional mechanical, electrical, and barrier properties. However, incorporating graphene into materials can be challenging. Existing methods often rely on graphene oxide (GO) or reduced graphene oxide (rGO), which require harsh chemical treatments and long processing times.

The UTM team has pioneered a rapid, simple, and biocompatible exfoliation method to produce few-layer graphene (FLG) flakes. This “greener” approach allows them to create PVA films containing FLG through a simple co-mixing and casting process. The resulting composite films exhibit significantly improved mechanical strength (Young’s modulus), electrical conductivity, and oxygen barrier properties. The optimal concentration of FLG was found to be around 1%. Intriguingly, the size of the FLG flakes also plays a crucial role. Larger flakes enhance strength, while smaller flakes improve flexibility. The films achieved relatively high electrical conductivity at low FLG concentrations, surpassing that of GO(rGO) composites.

This breakthrough has significant implications for various industries. The enhanced oxygen barrier properties could lead to improved food packaging, extending shelf life and reducing waste. The increased strength and flexibility make these films ideal for use in coatings and flexible electronic devices. The UTM team’s eco-friendly exfoliation method offers a sustainable pathway to produce high-performance composite materials.

Looking ahead, researchers plan to explore further applications of these FLG-enhanced PVA films, including using them in biomedical applications and water treatment. This research showcases the potential of graphene to revolutionize material science while promoting environmentally responsible manufacturing practices.

DOI: https://doi.org/10.1016/j.cscee.2025.101237