Imagine a future where broken bones heal seamlessly with implants that simply dissolve away once their job is done, eliminating the need for a second surgery. Bioabsorbable magnesium (Mg) alloys hold immense promise for this application, but their corrosion rate within the body has been a key challenge. Researchers at Universiti Teknologi Malaysia (UTM) have made a significant breakthrough in understanding this process, paving the way for more reliable and predictable bioabsorbable implants.

The central question addressed by the UTM team was: what are the key drivers of Mg alloy corrosion within the body? While both pH levels and chloride concentration were suspected to play a role, their individual contributions remained unclear. To solve this, the UTM researchers designed a novel experimental setup to isolate and quantify the effects of each factor on the corrosion kinetics of bioabsorbable Mg alloys. Their in vitro tests produced a surprising result: variations in chloride concentration, at levels relevant to biomedical applications, had a negligible impact on corrosion kinetics. Instead, they identified pH as the dominant factor in the degradation of these alloys. This is a critical finding because pH levels can fluctuate within the body due to various physiological processes.

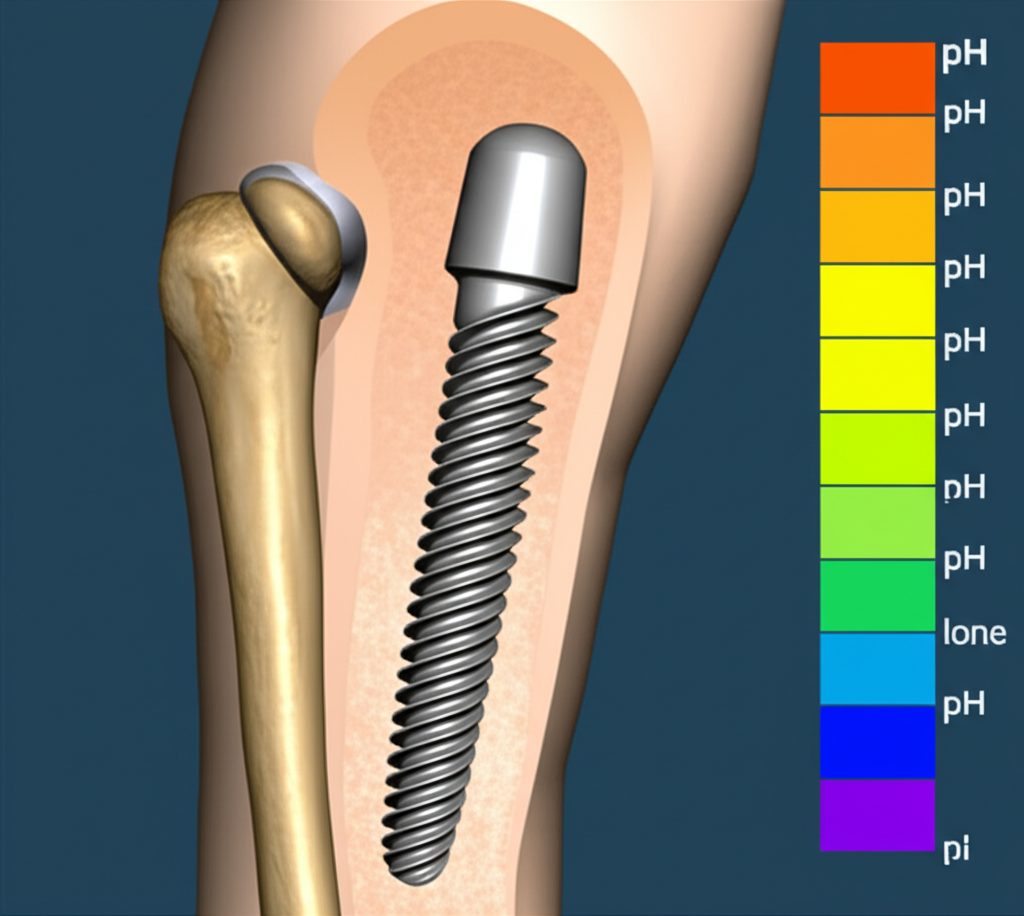

To further validate their experimental results and to develop a predictive tool, the team developed a phase-field model. This model not only accurately predicted the corrosion performance observed in the experiments but also demonstrated the capability to account for mechano-chemical effects during corrosion. This allows simulating and assessing the performance of bioabsorbable Mg alloy implants in practical orthopedic applications such as bone fracture fixation and porous scaffolds for bone tissue engineering.

The implications of this research are far-reaching. By pinpointing pH as the primary driver of corrosion, scientists and engineers can now focus their efforts on developing Mg alloys and coatings that are more resistant to pH changes within the body. This could lead to the creation of bioabsorbable implants with predictable lifespans, tailored to specific medical needs. In the future, this work could greatly improve the reliability and efficacy of bioabsorbable magnesium implants, offering patients a less invasive and more comfortable healing experience. The team’s phase-field model offers a powerful tool for assessing the in vitro and in vivo service life of bioabsorbable Mg-based biomedical devices, potentially accelerating the development and adoption of these innovative medical solutions.

https://doi.org/10.1016/j.rineng.2025.105746