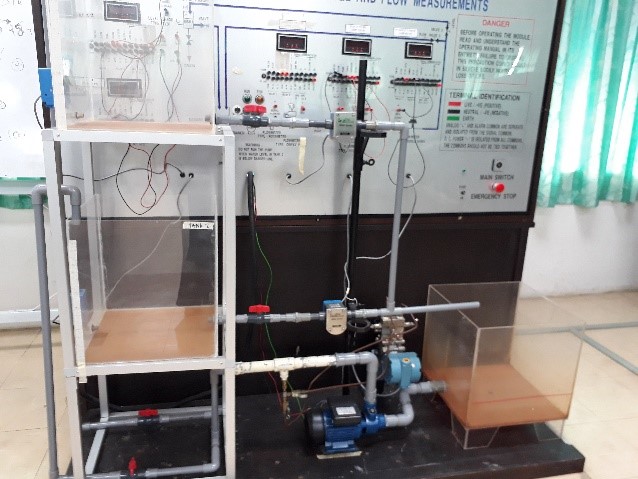

Liquid level system is commonly used in the process industry, either in the food industry, water industry even in the oil and gas industry. Each application comes with a stringent requirement complying to each of the industry’s security level. As an academician, to instill the importance of process system in the industry, an initiative on salvaging usable components from obsolete experimental setup in the unversity was initiated in 2017 in Industrial Process Control (SKEE4173) class with the help of a good colleague, Tuan Hj Mohamad Shukri Abdul Manaf as well as an unofficial industrial collaborator from ZEC Engineering Sdn. Bhd. The obsolete experimental set-up was a water level system. The initial salvaging works are shown in Figures 1 – 3.

Figure 1 |  Figure 2 |

Figure 3 |

The components taken from these obsolete experimental set up include three 3-phase 0.75kW motors, two variable speed drives, two flow rate sensors and two LVDT sensors for water level. In addition, the water tanks as well as the base of the experimental was cleared and re-used as the new system. Before re-using them, the components are tested to ensure that they are operational. Water tanks are modified and re-arranged on the existing set-up, all done by the final year students. The three 3-phase motors were serviced by ZEC Engineering Sdn. Bhd. prior to system set-up. Once the motors are fully serviced, they are then connected to the newly-designed laboratory-scaled water level system set-up. The connection of these components were figured out before-hand before the final installation of the system, along with pipes installation. Finally the water transfer process of the newly-design water level system is tested. Yes, all processes involved these final year students and everyone was contented having the opportunity to be involved.

The final first-phase water level process system fabricated is given in Figure 4 (2017), which was later upgraded to Figure 5. From figure 5, the level sensors are replaced with an e-tape level sensor (from an LVDT sensor). In addition, a new set of incoming and outgoing flow rate sensor are also installed.

Figure 4 |  Figure 5 |

The water level system is designed loosely based on a water distribution system applied in the water industry. Hence a collaboration with the local water utility comp company was initiated with Ranhill SAJ Sdn. Bhd. (Figure 6 and Figure 7).

Figure 6 |  Figure 7 |

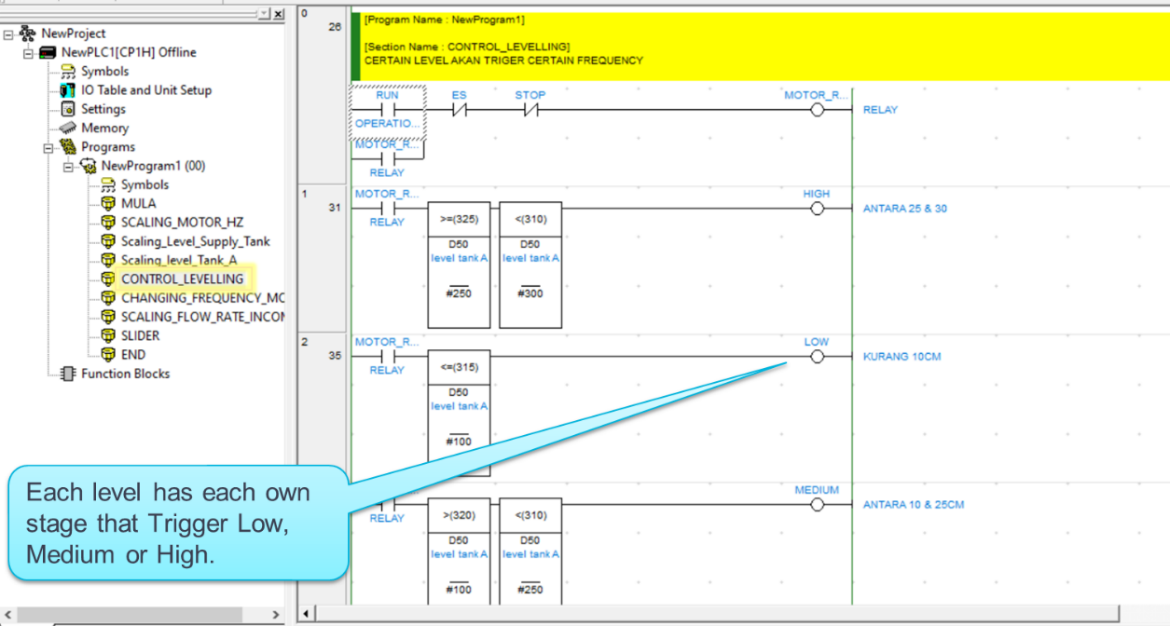

Since then, the laboratory-scaled system has been gradually updated, and connected to an HMI which monitors and controls the whole system. The work was conducted by several FYP students under my supervision, hence the progress is slowly but surely. The system is currently able to be automatically controlled by a PLC OMRON CPH1 through a ladder diagram, established by student in 2020 and later upgraded by another student this year. Figure 8 shows the latest programming of the automation part of the system in ladder diagram.

Figure 8 |

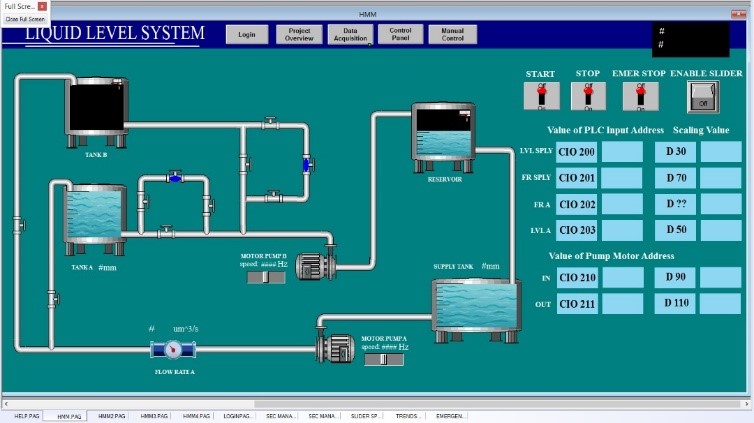

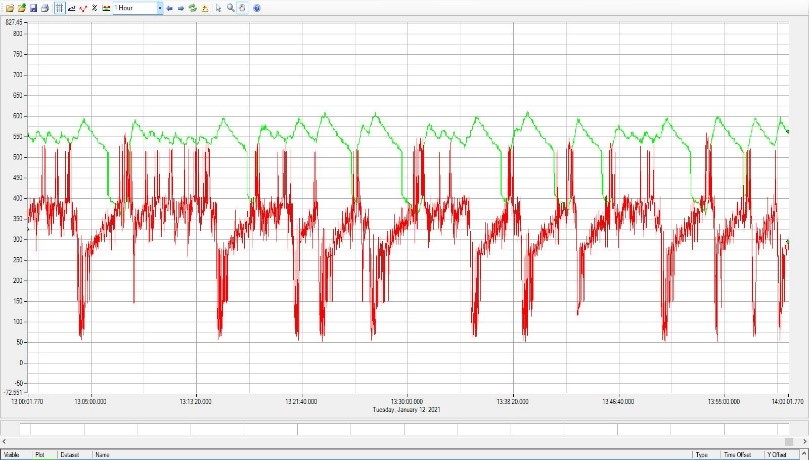

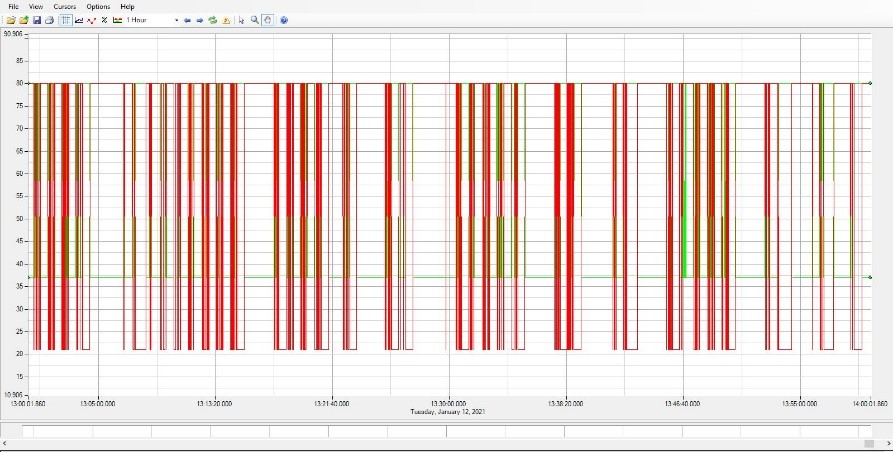

Currently, the system can be monitored and control on OMRON CX-supervisor (Figure 9). Data has been successfully collected, and the trending of the sensors can be viewed in real-time through the HMI (Figure 10).

Figure 9 |

Figure 10a |  Figure 10b |

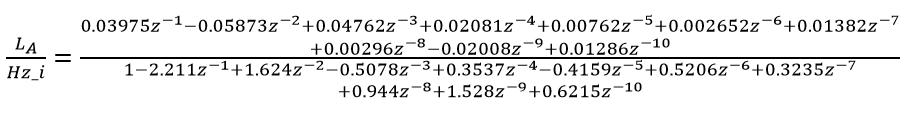

These data are collected within 1 second interval, hence system modeling of the system can be implemented, whereby the reservoir tank is controlled. The first mathematical modeling attempt was successful in establishing the relationship between the reservoir tank, as the output system, to the incoming motor frequency, obtained using prediction error minimization (PEM), which yield a sixth order system with a best fit of 99.99%. The attainment of the mathematical model is the first step on remote automated control for a real system, hence this stage, although seems trivial, is a significant result.

As a conclusion, currently, there are two concurrent research being applied. Firstly, to connect the automated liquid level system to a microcontroller, an Arduino in particular (Figure 11). This is to extend the system for a remote monitoring and control, as well as applying predictive maintenance to the system through the application of AI, using python as the programming language. Secondly, optimized controller is being applied to the mathematical model, with the final objective to apply the designed controller to the laboratory set-up. Wish us luck!

Figure 11 |

More about CAIRO UTM:

CAIRO UTM (Centre for Artificial Intelligence & Robotics) is one of the leading Centres of Excellence in Malaysia focusing on Artificial Intelligence, Robotics, Control and Automation. Established in 1997, CAIRO UTM has produced numerous talents and significant research outcomes on AI & Robotics. In 2018, CAIRO UTM was awarded as one of the Competence Centre by the Ministry of International Trade and Industry MITI. UTM has strong linkages and networking with academic institutions, government sectors and industrial sectors, on national and international level.

Recent Comments