On September 4, 2024, Associate Professor Ir. Ts. Dr. Nor Hasrul Akhmal Bin Ngadiman, a prominent researcher in additive manufacturing for medical devices and also a Fellow at the Medical Devices and Technology Center (MEDiTEC) from from Universiti Teknologi Malaysia (UTM), made significant contributions at the Stratasys-IME event, “Innovation Unleashed: The Future with Additive Manufacturing.” The event, held at the Courtyard by Marriott Kuala Lumpur South, attracted industry leaders and innovators across South East Asia (SEA), focusing on how additive manufacturing is revolutionizing sectors like healthcare, automotive, and education.

Co-organized by IME Trading Sdn Bhd and Stratasys, one of the world’s leading 3D printer manufacturers, the event showcased the impact of additive manufacturing in transforming the Malaysian manufacturing landscape. Dr. Nor Hasrul participated in two key sessions: a panel discussion titled “Driving Innovation with Additive” and a public lecture on the role of additive manufacturing in medical devices.

Panel Discussion: Driving Innovation with Additive

During his panel session, Dr. Nor Hasrul highlighted the transformative benefits of additive manufacturing, especially in the medical device sector. Leveraging his expertise as a Fellow at the Medical Devices and Technology Center (MEDiTEC), he shared insights into how 3D printing is enabling the development of custom medical implants, surgical guides, and dental devices.The technology allows for rapid prototyping, reduced material waste, and highly personalized solutions tailored to individual patient needs.

In addition to the technical aspects, Dr. Nor Hasrul emphasized universities’ pivotal role as a bridge between theoretical knowledge and practical applications. He stressed the importance of industry participation in research and development (R&D), calling for greater collaboration among universities, industry, government, and the community. His key takeaway message during the discussion was clear:

“Collaboration between academia and industry is crucial to unlocking the full potential of additive manufacturing in Malaysia. By working together, we can bridge the skills gap, drive innovation, and ensure that our manufacturing sector remains competitive in the global market. Investing in education and partnerships today will pave the way for a stronger, more agile industry tomorrow.”

The event facilitated robust conversations on the role of Industry 4.0 technologies in Malaysia’s future. Dr. Nor Hasrul pointed out that the country could harness these advanced technologies with strategic partnerships to bolster its global manufacturing competitiveness.

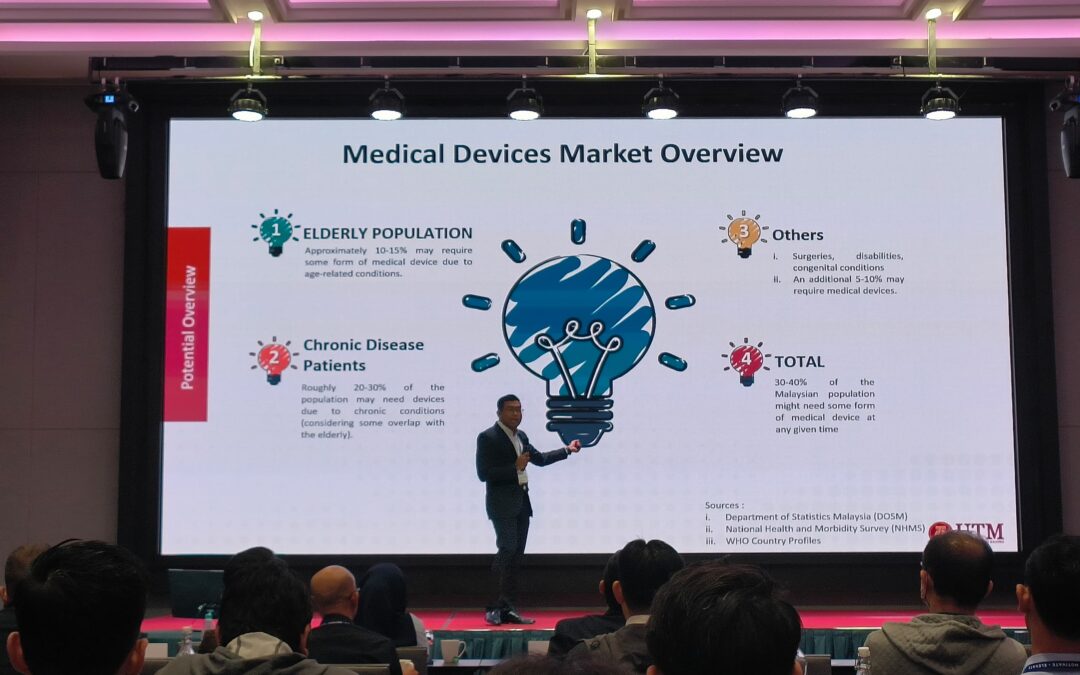

Public Lecture: Additive Manufacturing for Medical Devices

In his public lecture, Dr. Nor Hasrul provided an in-depth exploration of the applications of additive manufacturing specifically within the medical devices industry. He discussed how 3D printing technology is revolutionizing the production of patient-specific medical devices, including custom implants, prosthetics, and surgical guides. By leveraging 3D printing, the medical industry is now able to produce highly detailed and accurate devices, improving patient outcomes and reducing the time required for manufacturing.

Dr. Nor Hasrul’s lecture also touched upon future trends in the medical field, such as bio-printing and the use of advanced materials for creating more durable and biocompatible medical products. He emphasized that these innovations could significantly improve patient care while also lowering production costs.

Conclusion

By contributing to both the panel discussion and the public lecture, Dr. Nor Hasrul provided a comprehensive view of how additive manufacturing is set to shape the future of industries in Malaysia. His insights not only underscored the importance of embracing Industry 4.0 technologies but also called for stronger collaboration between academia and industry to drive innovation and global competitiveness. The Stratasys-IME event provided an invaluable platform for industry leaders to exchange ideas and explore the transformative potential of additive manufacturing.