Membrane Technology: A Sustainable Environmental and Industrial Solution

Membrane-based separation is a sustainable and dignified technology that offers immense benefits to the mankind. >>>

Membrane filtration systems combine the innovative system designs and engineered high performance membranes for a wide spectrum of fluid separation applications ranging from desalination and wastewater treatment to greenhouse gas removal. Advanced Membrane Technology Research Centre (AMTEC), Universiti Teknologi Malaysia (UTM) is one of the leading research centres that has constantly engaged with its indigenous and advanced research and development of membrane technology to provide ultimate solutions to the current environmental and industrial problems.

What is Membrane?

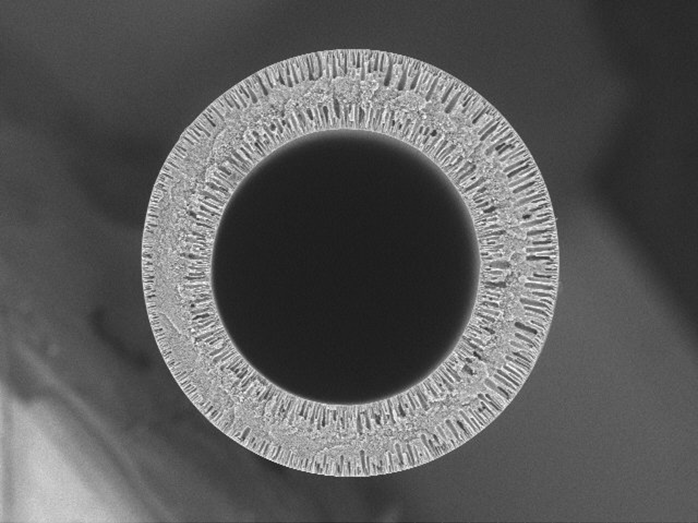

“Membrane” originates from latin word, membrana, which means skin. Membrane is regarded as a selective barrier between two phases, usually a solid film, and occasionally a fluid film of a small but observable thickness.

Development of membranes dates back to 1748, where Abbé Nolet coined the word ‘osmosis’ to describe the permeation of water through a diaphragm. Early researches on membranes usually involved biological membranes comes from animals such as bladders of pigs, cattle or fish and sausage casings made of animal gut, until the first synthetic nitrocellulose membranes were successfully prepared in laboratories around the 1900s.

To date, the pace of membrane technology steadily increases as it covers a wide variety of chemical and physical applications mainly because membranes offer ease of operation, economic viability for smaller unit operations, low energy cost, compactness, and so on. Generally speaking, membrane is attractive because of its unique ability to permeate specific components pass through it. This ability was being exploited for quite a number of

applications and yet still growing for new commercial purposes. Microfiltration (MF), ultrafiltration (UF), nanofiltration (NF), reverse osmosis (RO), electrodialysis (ED), membrane electrolysis (ME), diffusion dialysis (DD), and dialysis is the first generation of membrane processes developed since 1920s. Loeb and Sourirajan’s works on preparation of anisotropic membrane for reverse osmosis application in 1960s has been a paradigm shift in membrane technology. Separation through thin dense membrane favors separation in molecular level leads to emergence of state-of-the-art second generation membrane processes namely gas and vapor separation, membrane distillation (MD), pervaporation (PV), membrane contactors (MC) and carrier mediated process and yet, still evolving and intensely studied.

The performance of a membrane is characterised by its permeability and selectivity. The membrane’s ability to permit specific penetrant pass through the membrane, known as the permeability whereas, selectivity is the membrane’s ability to allow certain species to pass through it but not the other. Membrane economics are closely linked to their transport properties: permeability, which determines separation productivity; and selectivity, determines the separation efficiency.

These mechanisms of permeability and selectivity are driven by differences in driving force. Separation by membranes will be propelled with the presence of driving force. Different applications will require different driving force to perform the specific separation. For instance, water separation and purification by the use of membrane (MF, UF and RO) requires pressure to achieve the separation. On the other hand, separation of vapor and gas mixtures propelled by the presence of concentration gradient.