List of Advanced Testing Equipments

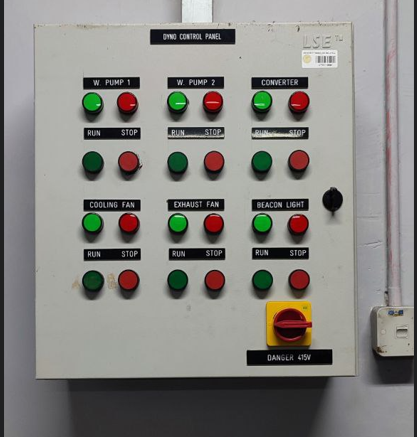

DYNO Control Panel

The DYNO control panel is a crucial component in the operation and management of the dynamometer setup used for testing the Lycoming O-320 engine.

This control panel integrates several key systems to ensure the efficient and safe operation of the dynamometer and the associated engine testing environment.

The control panel includes two water pumps, labeled as Water Pump 1 and Water Pump 2. These pumps are essential for regulating the cooling water flow through the dynamometer.

A converter is also part of the DYNO control panel. This device is responsible for converting electrical power to the appropriate form needed by the dynamometer and its auxiliary systems.

The cooling fan and exhaust fan are integral to managing the thermal environment within the testing area.

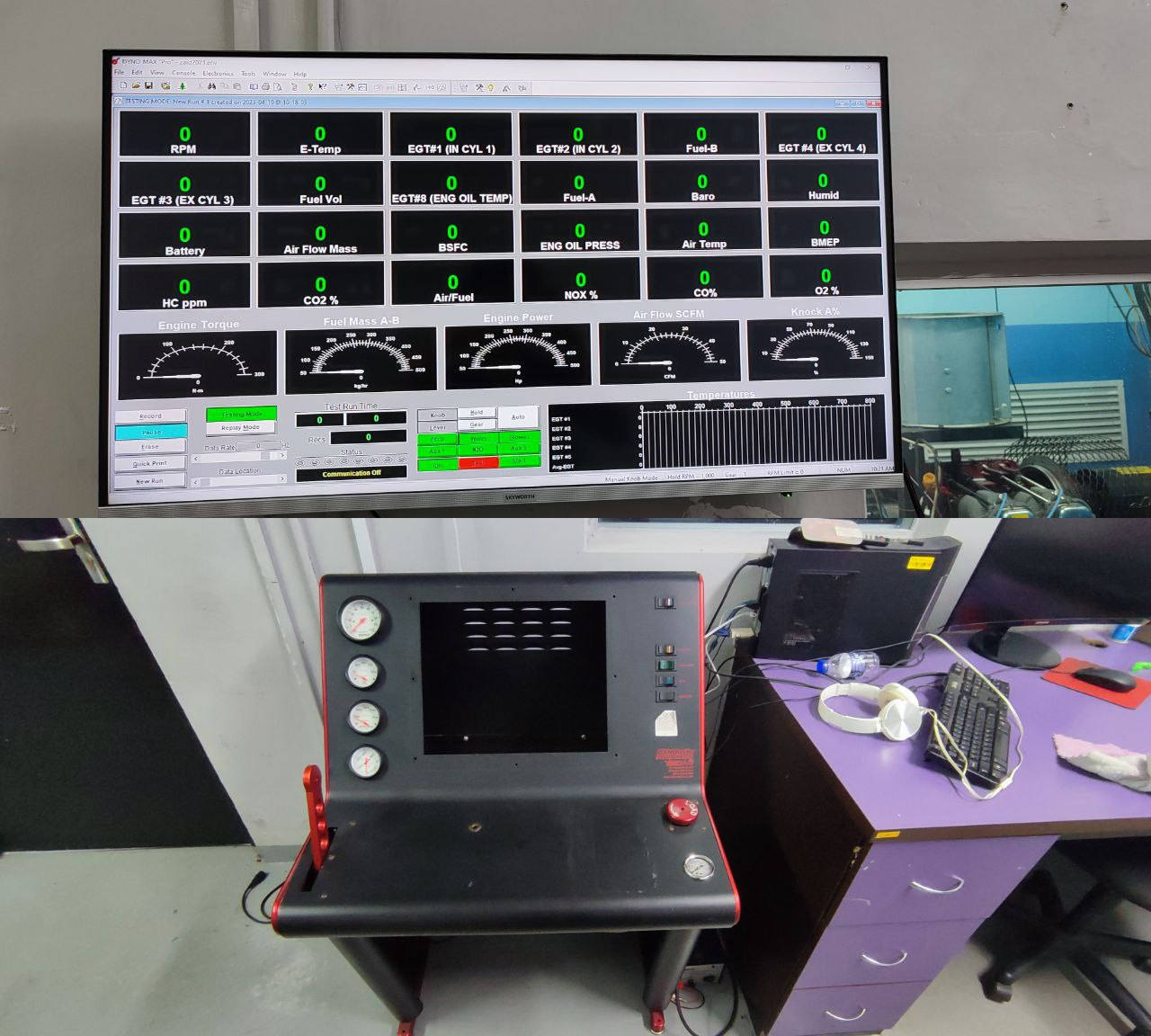

DYNOmite Data Acquisition and Control Software

The DYNOmite data acquisition and control software is a sophisticated tool designed to enhance the capabilities of dynamometer systems used with the Lycoming O-320 engine.

This software facilitates comprehensive monitoring, recording, and analysis of engine performance data in real-time. One of its key features is data acquisition, where it collects data from various sensors attached to the engine and dynamometer, including measurements of torque, RPM, temperature, pressure, and exhaust gas composition.

This allows for a detailed assessment of engine performance under different operating conditions, providing invaluable insights for both research and practical applications.

The DYNOmite software also excels in data analysis and reporting. It offers powerful analytical tools to process the collected data, generating graphs, charts, and comprehensive reports that aid in the interpretation of results and the identification of trends and anomalies.

DYNOmite EMS Gas Analyzer MODEL 5002

The DYNOmite EMS Gas Analyser 5002, used in conjunction with the Lycoming O-320 engine, is an advanced tool for exhaust gas analysis. This analyser is capable of measuring various exhaust gas components, including oxygen (O2), carbon monoxide (CO), carbon dioxide (CO2), hydrocarbons (HC), and nitrogen oxides (NOx). These measurements are crucial for evaluating the combustion efficiency, air-fuel ratio, and emissions of the engine.

The DYNOmite EMS Gas Analyser 5002 provides real-time data, enabling precise monitoring and adjustments during engine tests. This integration enhances the capability to conduct detailed studies on engine performance, emissions control, and environmental impact.

The comprehensive data collected through the DYNOmite EMS Gas Analyser 5002 is invaluable for both academic research and practical applications in the field of automotive and aerospace engineering.